One Stage Versus Two Stage Air Compressors

The working principle of both types of air compressors is the same.

One stage versus two stage air compressors. Air compressors come in two types. This is the most common type of ac system. The compressed air isn t sent to a storage tank. The unit is either switched on and running or switched off completely with nothing in between.

A single stage compressor compresses once a two stage twice. It s instead sent to a smaller piston for a second stroke this time at roughly 175 psi. A two stage air conditioner is a cooling system with a compressor that operates at two different capacities. A single stage air conditioner s compressor only works one level of operation cooling your home at full blast.

Unlike a traditional air conditioner which has a compressor that is always running at full blast a two stage air conditioner s compressor has both a medium and a high capacity. One stage air conditioner. The process within a two stage compressor alternately referred to as a dual stage compressor is similar to that of a single stage but with one variation. A two stage air conditioner s compressor works at two levels of operations.

Two stage systems feature two. Your existing unit is likely a single stage ac. Efficiency considerations since a one stage air conditioner is always operating at its full capacity it is always using the maximum amount of energy. A single stage air conditioner has a single compressor speed.

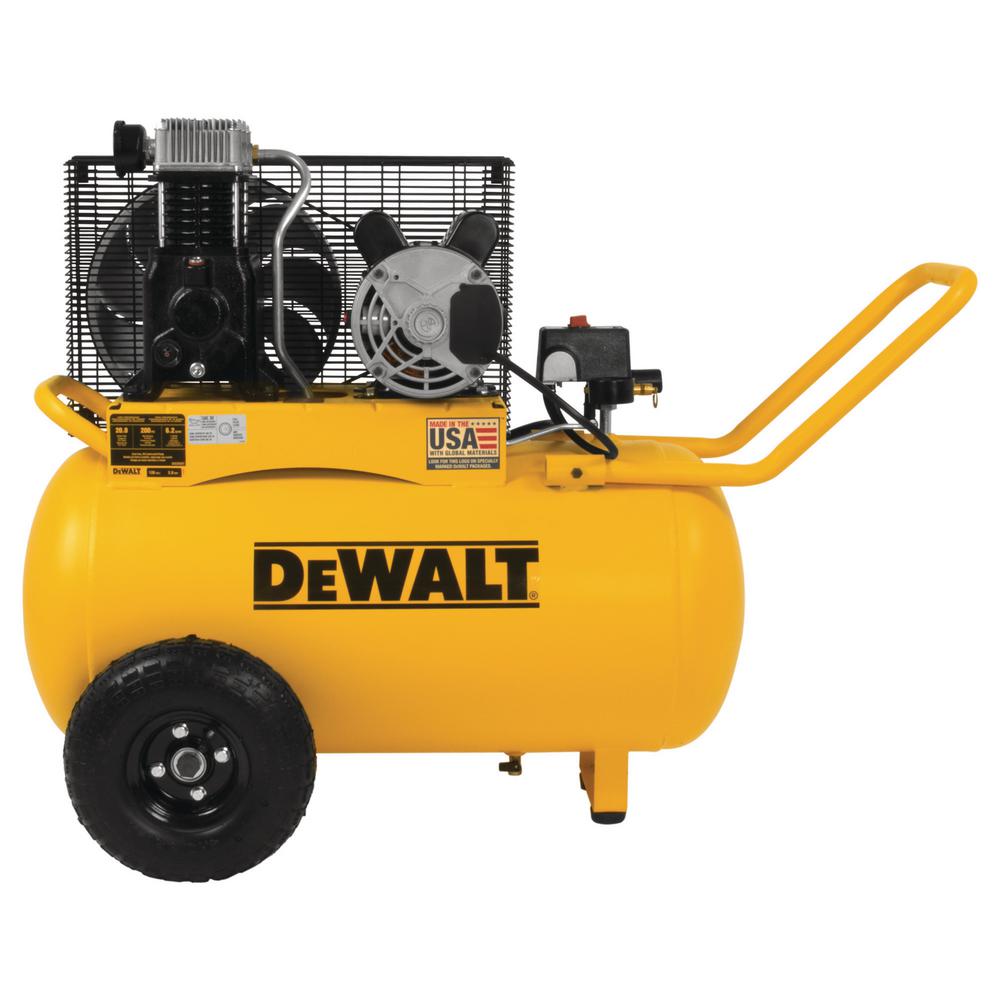

The single and two stage most prospective buyers ask the difference between single stage vs 2 stage air compressor before making a purchase. The big difference between a single stage compressor and a two stage compressor is the number of times air gets compressed once it is taken in. High for hot summer days the equivalent of full blast for single stage acs low for milder days when you don t need as much cooling. Two stage compressors can manage larger loads up to 200psi.

In addition a one stage air conditioner goes through briefer and more frequent cooling cycles than a two stage system. The major difference is the number of times the air gets compressed between the inlet valve and the tool nozzle.